Collection: Air Compressors

Air Compressors — Types, Benefits and Use Cases All In One Place Air Compressors: The Ultimate Guide to Types, Benefits and Use Cases

Introduction

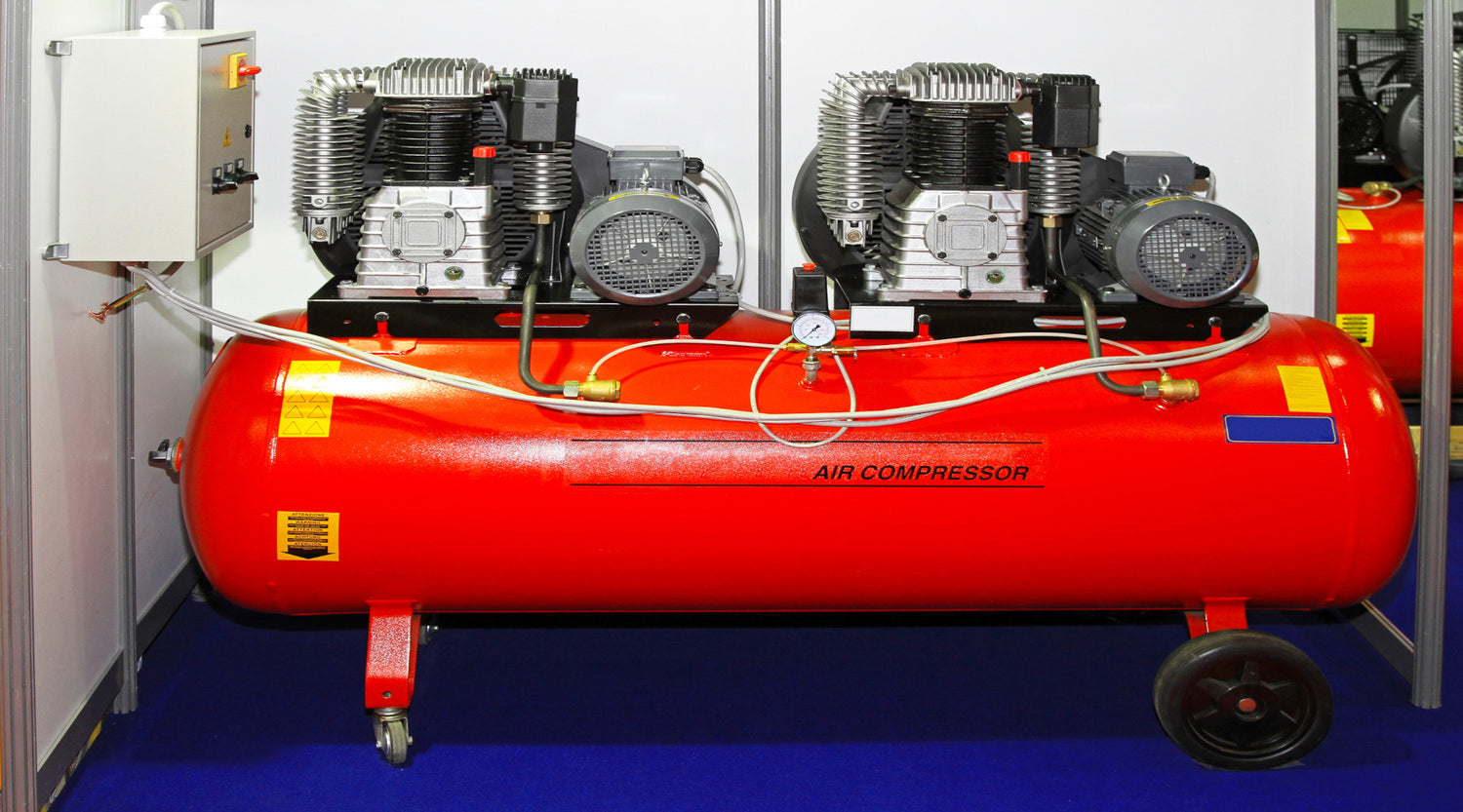

Air compressors are robust multifunctional machines used in various industries. Compressors are used in almost every industrial sector, from Automotive to Building and Manufacturing. When selecting one, the key is knowing which type fits your application best. To do this, the purchaser must clearly understand each type's use cases and benefits, to properly select the correct compressor for your purpose. In this section, we will cover the history of air compressors, go over the main types (reciprocating and rotary screw) and talk about what they do and don’t like, and finally get you started on choosing an Air Compressor.

The History of Air Compressors: a Quick Introduction.

The Egyptians used some of the earliest air compressors, which were simple bellows used in metalworking shops. This technology is still in use today. The next big leap forward was during the Industrial Revolution. Mechanical Air Compressors were used to power drilling machines in mines. These compressors were steam-powered, cumbersome, and custom-built for their application.

The next transformation occurred in the 1930s; this was when rotary screw compressors were introduced. Screw Compressors gave the following benefits.

- They were quieter

- More efficient

- More reliable.

The main types of air compressors in use today are:

- Rotary Screw Compressors

- Reciprocating (Piston) Air Compressors

- Belt Drive Air Compressors

- Direct Drive Air Compressors

Choosing the Right Air Compressor

When selecting the right compressor for your application, here are some of the things to consider:

- Type of Use: Decide if you want continuous airflow or high-pressure bursts on and off. Reciprocating Air compressors are best for single use; rotary screw air compressors can be used continuously.

- Pressure and Airflow Required: Based on your tools and applications, calculate the required pressure (in PSI) and airflow requirement (in CFM). Think about the receiver (air tank) size too.

- Conditions to be used: Rotary screw air compressors are quieter and perfect for use in an enclosed or noisy environment. Direct-drive air compressors can be a smaller option if space is a concern.

- Budget: Rotary screw air compressors can cost more upfront but are durable and effective for the industrial market. Reciprocating air compressors are cheaper and generally more appropriate for smaller projects.

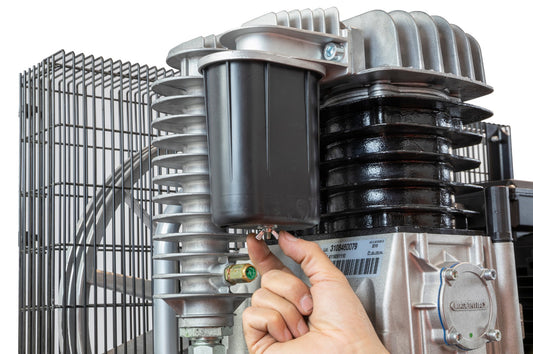

- Maintenance: Assess whether you have the resources and know-how to maintain each type.

Conclusion

Air compressors are an indispensable piece of equipment for many types of businesses, from garages to factories. Knowing the differences between a reciprocating and rotary screw compressor and whether you should go for the belt-driven or direct-drive reciprocating compressor is critical to selecting the proper compressor for your application.

Reciprocating compressors are a great economical choice for intermittent use, with belt-driven models being quieter and more durable, while direct-drive is smaller and requires less maintenance. Alternatively, rotary screw compressors are the best for heavy-duty use, and they are also very quiet and efficient for the industrial market.

You can choose wisely and invest in an air compressor that’s better for your work environment, budget, and maintenance needs based on your application, application, and desired longevity.